At Leadshine, we provide high-quality industrial servo drive solutions designed for modern machinery that demands precision, efficiency, and reliability. Our servo drives are engineered to deliver accurate motion control across a wide range of industrial applications. By combining advanced control technology with robust design, industrial servo drives from Leadshine ensure smooth and responsive operation in demanding environments. These drives are compatible with various motors and systems, offering flexibility for automation projects of all sizes.

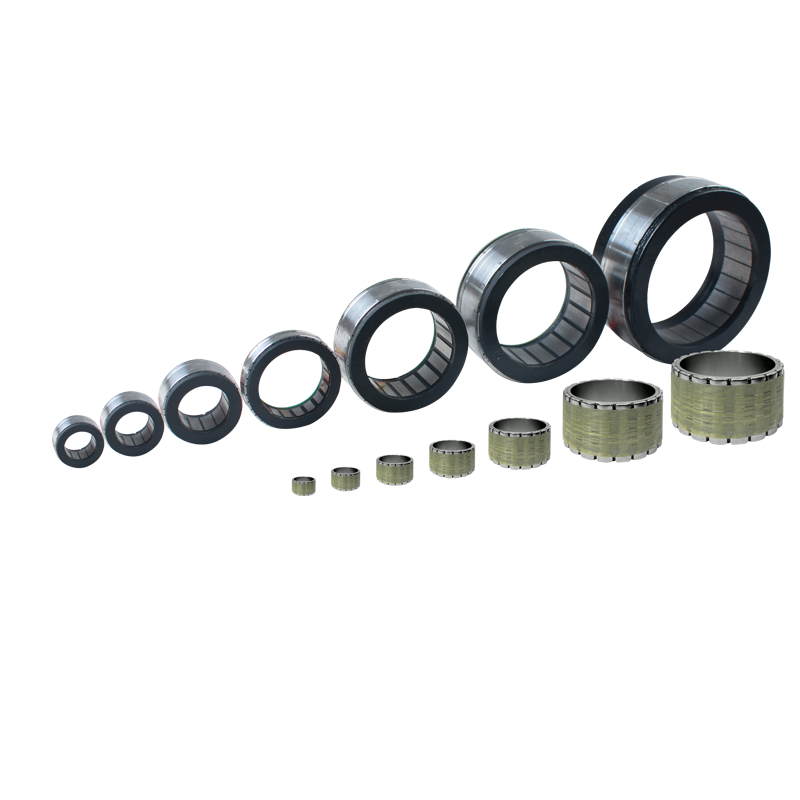

Stepper Motor Sizes and Options

In addition to servo drives, Leadshine offers a broad selection of stepper motors, including our CM Series 2-phase hybrid stepper motors. The CM Series covers sizes from NEMA 08 (20mm) to NEMA 42 (110mm) and delivers torque up to 28 N·m, providing high performance for a wide range of applications. Our stepper motor sizes include NEMA 8, 11, 14, 16, 17, 23, 24, 34, and 42. Among these, NEMA 17 and NEMA 23 stepper motors are particularly popular for their balance of torque, size, and versatility. By offering multiple stepper motor sizes, including the CM Series, engineers can select the optimal motor for each application, whether it is for compact automation systems or larger industrial machinery.

Integration and Compatibility

A key advantage of using Leadshine products is the seamless compatibility between our industrial servo drives and stepper motors. Our drives are designed to work efficiently with a variety of motor sizes, providing precise control over speed, position, and torque. This integration reduces installation complexity and ensures that machines operate at peak performance. By standardizing control systems, businesses can simplify maintenance and improve overall operational reliability.

Performance Benefits

Using the right industrial servo drive in combination with appropriately sized stepper motors offers several performance benefits. Operators experience smoother motion, higher accuracy, and faster response times. Properly matched drives and motors also reduce energy consumption and minimize mechanical stress, which contributes to longer equipment life. With Leadshine, customers gain the confidence that their machinery will perform consistently under demanding conditions, enhancing productivity and reducing downtime.

Applications Across Industries

Leadshine's range of stepper motors and industrial servo drives serves industries such as CNC machining, robotics, packaging, and automated assembly. By providing various stepper motor sizes and compatible drives, we enable businesses to customize solutions for precise motion control. Whether the application requires compact motors for small devices or larger motors for heavy-duty machinery, our products meet the needs of diverse industrial environments.

Conclusion

Selecting the right components for motion control is crucial for achieving efficiency and precision in modern machinery. Industrial servo drives and stepper motors of various stepper motor sizes provide the flexibility and performance required for a wide range of applications. At Leadshine, we combine over 27 years of expertise with a commitment to quality, ensuring that our products meet the demands of industrial automation. By choosing our solutions, businesses can optimize machine performance, simplify system design, and maintain reliable operation across diverse industries.